гӮ«гғјгғңгғігғӘгғ иЈҪйҖ гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјеҺҹж–ҷгҒӢгӮүгғӘгғ е®ҢжҲҗе“ҒгҒҫгҒ§

гӮ«гғјгғңгғігғӯгғјгғүгғӘгғ гҒЁйҖҡеёёгҒ®гғӣгӮӨгғјгғ«гҒ®йҒ•гҒ„гӮ’зҹҘгӮҠгҒҹгҒ„гҒЁжҖқгҒЈгҒҹгҒ“гҒЁгҒҜгҒӮгӮҠгҒҫгҒӣгӮ“гҒӢпјҹ гӮ«гғјгғңгғігғӘгғ гҒҜеҚҳгҒ«и»ҪйҮҸгҒӘгҒ гҒ‘гҒ§гҒӘгҒҸгҖҒгӮ№гғ”гғјгғүгҖҒгғҸгғігғүгғӘгғігӮ°гҖҒгҒқгҒ—гҒҰе…ЁдҪ“зҡ„гҒӘд№—гӮҠеҝғең°гӮ’еҗ‘дёҠгҒ•гҒӣгӮӢгӮҲгҒҶгҒ«иЁӯиЁҲгҒ•гӮҢгҒҰгҒ„гҒҫгҒҷгҖӮ

гҒ“гҒ®гӮ¬гӮӨгғүгҒ§еӯҰгҒ¶еҶ…е®№гҒҜж¬ЎгҒ®гҒЁгҒҠгӮҠгҒ§гҒҷгҖӮ

жңӘеҠ е·ҘгҒ®гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгҒҢе®ҢжҲҗгҒ—гҒҹгғӘгғ гҒ«еӨүгӮҸгӮӢж§ҳеӯҗгҖӮ

иЁӯиЁҲгҖҒжҲҗеҪўгҖҒд»•дёҠгҒ’гҒ«гҒҠгҒ‘гӮӢйҮҚиҰҒгҒӘгӮ№гғҶгғғгғ—гҖӮ

е®үе…ЁжҖ§гҒЁгғ‘гғ•гӮ©гғјгғһгғігӮ№гӮ’дҝқиЁјгҒҷгӮӢе“ҒиіӘгғҒгӮ§гғғгӮҜгҖӮ

гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгҒЁгҒҜдҪ•гҒ§гҒҷгҒӢ?

гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгҒҜгҖҒзӮӯзҙ еҺҹеӯҗгҒ®зҙ°гҒ„жқҹгҒӢгӮүдҪңгӮүгӮҢгҒҹи»ҪйҮҸгҒ§й«ҳеј·еәҰгҒ®зҙ жқҗгҒ§гҒҷгҖӮгҒ“гӮҢгӮүгҒ®з№Ҡз¶ӯгҒҜгҖҒдәәй–“гҒ®й«ӘгҒ®жҜӣгҒ®зҙ„10еҲҶгҒ®1гҒ®зӣҙеҫ„гҒ§гҒҷгҖӮгҒ“гӮҢгӮүгҒ®жқҹгҒҜйҖҡеёёгҖҒгӮ·гғјгғҲзҠ¶гҒ«з№”гӮҠиҫјгҒҫгӮҢгҒҹгӮҠгҖҒжЁ№и„ӮгҒЁж··еҗҲгҒ•гӮҢгҒҰиЈҪйҖ з”ЁгҒ®гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгғ—гғӘгғ—гғ¬гӮ°гҒ«еҠ е·ҘгҒ•гӮҢгҒҫгҒҷгҖӮдҝЎгҒҳгӮүгӮҢгҒӘгҒ„гҒ»гҒ©гҒ®и»ҪгҒ•гҒЁдёҰеӨ–гӮҢгҒҹеј·еәҰгҒЁгҒ„гҒҶгҖҒгҒ—гҒ°гҒ—гҒ°зӣёеҸҚгҒҷгӮӢзү№жҖ§гӮ’е…јгҒӯеӮҷгҒҲгҒҰгҒ„гӮӢгҒҹгӮҒгҖҒгҖҢгӮ№гғјгғ‘гғјгғһгғҶгғӘгӮўгғ«гҖҚгҒЁиЁҖгҒҲгӮӢгҒ§гҒ—гӮҮгҒҶгҖӮ

гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгҒ«гҒҜT700гӮ„T800гҒӘгҒ©ж§ҳгҖ…гҒӘзЁ®йЎһгҒҢгҒӮгӮҠгҖҒгҒқгӮҢгҒһгӮҢзӢ¬иҮӘгҒ®еүӣжҖ§гҒЁеј·еәҰзү№жҖ§гӮ’еӮҷгҒҲгҒҰгҒ„гҒҫгҒҷгҖӮй«ҳжҖ§иғҪгӮ«гғјгғңгғігғӘгғ гӮ’иЈҪйҖ гҒҷгӮӢгҒ«гҒҜгҖҒйҒ©еҲҮгҒӘзЁ®йЎһгӮ’йҒёжҠһгҒҷгӮӢгҒ“гҒЁгҒҢйҮҚиҰҒгҒ§гҒҷгҖӮ

гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгҒ®ж§ӢйҖ гҒЁгҒқгҒ®еҲ©зӮ№гҒ®з°ЎеҚҳгҒӘжҰӮиҰҒгҒҜж¬ЎгҒ®гҒЁгҒҠгӮҠгҒ§гҒҷгҖӮ

|

гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјж§ӢйҖ

|

иӘ¬жҳҺ

|

дё»гҒӘеҲ©зӮ№

|

|

еҚҳз№Ҡз¶ӯгӮ№гғҲгғ©гғігғү

|

зҙ°гҒ„зӮӯзҙ еҺҹеӯҗгҒҢз№Ҡз¶ӯзҠ¶гҒ«зөҗеҗҲгҒ—гҒҹ

|

и»ҪйҮҸгҖҒй«ҳеј•ејөеј·еәҰ

|

|

гғ•гӮЎгӮӨгғҗгғјжқҹ/гғҲгӮҰ

|

иӨҮж•°гҒ®гӮ№гғҲгғ©гғігғүгӮ’гӮ°гғ«гғјгғ—еҢ–

|

жүұгҒ„гӮ„гҒҷгҒҸгҖҒеқҮдёҖгҒӘгғ—гғӘгғ—гғ¬гӮ°

|

|

гғ—гғӘгғ—гғ¬гӮ°гӮ·гғјгғҲ

|

жЁ№и„ӮгҒЁзө„гҒҝеҗҲгӮҸгҒӣгҒҹз№Ҡз¶ӯ

|

еқҮдёҖгҒӘеј·еәҰгҒ§жҲҗеҪўгҒ—гӮ„гҒҷгҒ„

|

|

з©ҚеұӨеұӨ

|

иӨҮж•°гҒ®гӮ·гғјгғҲгӮ’йҮҚгҒӯгҒҰй…ҚзҪ®

|

й«ҳгҒ„еүӣжҖ§гҖҒж–№еҗ‘жҖ§гҒ®гҒӮгӮӢеј·еәҰ

|

|

е®ҢжҲҗгҒ—гҒҹгӮ«гғјгғңгғігғӘгғ

|

зЎ¬еҢ–гҒҠгӮҲгҒіж©ҹжў°еҠ е·ҘгҒ•гӮҢгҒҹгғӘгғ

|

и»ҪйҮҸгҖҒиҖҗд№…жҖ§гҖҒз©әж°—еҠӣеӯҰзҡ„

|

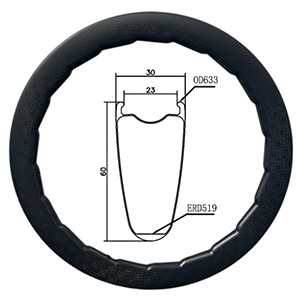

гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјиЈҪиҮӘи»ўи»ҠгғӘгғ гҒ®дё»гҒӘзү№еҫҙ

и»ҪйҮҸиЁӯиЁҲ: гғҗгӮӨгӮҜгҒ®е…ЁдҪ“йҮҚйҮҸгҒҢи»ҪжёӣгҒ•гӮҢгҖҒзҷ»еқӮгӮ„еҠ йҖҹгҒҢе®№жҳ“гҒ«гҒӘгӮҠгҒҫгҒҷгҖӮ

й«ҳгҒ„еүӣжҖ§: гғҡгғҖгғ«гҒӢгӮүи·ҜйқўгҒёгғ‘гғҜгғјгӮ’еҠ№зҺҮзҡ„гҒ«дјқйҒ”гҒ—гҖҒйҖҹеәҰгҒЁеҝңзӯ”жҖ§гӮ’еҗ‘дёҠгҒ•гҒӣгҒҫгҒҷгҖӮ

иҖҗд№…жҖ§: еҺігҒ—гҒ„жқЎд»¶дёӢгҒ§гӮӮз–ІеҠҙгҒ«иҖҗгҒҲгҖҒй•·жңҹй–“гҒ«гӮҸгҒҹгҒЈгҒҰгғ‘гғ•гӮ©гғјгғһгғігӮ№гӮ’з¶ӯжҢҒгҒ—гҒҫгҒҷгҖӮ

з©әеҠӣгғ—гғӯгғ•гӮЎгӮӨгғ«: йўЁгҒ®жҠөжҠ—гӮ’жёӣгӮүгҒ—гҒҰгӮ№гғ гғјгӮәгҒ§йҖҹгҒ„д№—гӮҠеҝғең°гӮ’е®ҹзҸҫгҒҷгӮӢеҪўзҠ¶гҖӮ

гӮ«гғјгғңгғігғӘгғ vs гӮўгғ«гғҹгғӘгғ

|

зү№еҫҙ

|

гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгғӘгғ

|

гӮўгғ«гғҹгғӘгғ

|

|

йҮҚгҒ•

|

йқһеёёгҒ«и»ҪйҮҸгҒ§гҖҒзҷ»еқӮгӮ„еҠ йҖҹгҒҢе®№жҳ“

|

йҮҚгҒҸгҒӘгӮҠгҖҒйҖҹеәҰеҠ№зҺҮгҒҢжӮӘгҒҸгҒӘгӮӢ

|

|

зЎ¬зӣҙжҖ§

|

е„ӘгӮҢгҒҹеӢ•еҠӣдјқйҒ”гӮ’е®ҹзҸҫгҒҷгӮӢй«ҳеүӣжҖ§

|

йҒ©еәҰгҒӘзЎ¬гҒ•гҖҒиІ иҚ·гҒҢгҒӢгҒӢгӮӢгҒЁжӣІгҒҢгӮӢе ҙеҗҲгҒҢгҒӮгӮҠгҒҫгҒҷ

|

|

иҖҗд№…жҖ§

|

йҒ©еҲҮгҒ«гғЎгғігғҶгғҠгғігӮ№гҒҷгӮҢгҒ°й•·жҢҒгҒЎгҒ—гҒҫгҒҷ

|

гӮ№гғҲгғ¬гӮ№гӮ’еҸ—гҒ‘гӮӢгҒЁгҖҒжӣІгҒҢгҒЈгҒҹгӮҠеүІгӮҢгҒҹгӮҠгҒ—гӮ„гҒҷгҒҸгҒӘгӮӢ

|

|

з©әж°—еҠӣеӯҰ

|

з©әж°—гҒ®жөҒгӮҢгӮ’жңҖйҒ©еҢ–гҒҷгӮӢеҪўзҠ¶гҒ«гҒ§гҒҚгӮӢ

|

йҷҗе®ҡзҡ„гҒӘз©әеҠӣеҪўзҠ¶

|

|

жҢҜеӢ•жёӣиЎ°

|

и·ҜйқўгҒ®жҢҜеӢ•гӮ’еҗёеҸҺгҒ—гҖҒгӮ№гғ гғјгӮәгҒӘд№—гӮҠеҝғең°гӮ’е®ҹзҸҫ

|

гғ©гӮӨгғҖгғјгҒ«гӮҲгӮҠеӨҡгҒҸгҒ®жҢҜеӢ•гӮ’дјқгҒҲгӮӢ

|

|

гӮ«гӮ№гӮҝгғһгӮӨгӮә

|

ж·ұгҒ•гҖҒе№…гҖҒгғ¬гӮӨгӮўгғғгғ—гӮ’гӮ«гӮ№гӮҝгғһгӮӨгӮәгҒ§гҒҚгҒҫгҒҷ

|

гӮ«гӮ№гӮҝгғһгӮӨгӮәгӮӘгғ—гӮ·гғ§гғігҒҢе°‘гҒӘгҒ„

|

гҒҷгҒ№гҒҰгҒ®гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгҒҢеҗҢгҒҳгҒ§гҒҜгҒӮгӮҠгҒҫгҒӣгӮ“гҖӮгӮ«гғјгғңгғігғӘгғ гҒ®иЈҪйҖ гҒ«дҪҝз”ЁгҒҷгӮӢзҙ жқҗгӮ’йҒёгҒ¶йҡӣгҒ«гҒҜгҖҒд»ҘдёӢгҒ®гӮҲгҒҶгҒӘйҒёжҠһиӮўгҒҢгҒӮгӮҠгҒҫгҒҷгҖӮ

гҒқгӮҢгҒһгӮҢгҒ®гӮҝгӮӨгғ—гҒ«гҒҜз•°гҒӘгӮӢж©ҹжў°зҡ„зү№жҖ§гҒҢгҒӮгӮӢгҒҹгӮҒгҖҒгғӘгғ гҒ®з”ЁйҖ”гҒЁгғ©гӮӨгғҖгғјгҒ®еҘҪгҒҝгҒ«еҗҲгҒЈгҒҹгӮӮгҒ®гӮ’йҒёжҠһгҒҷгӮӢгҒ“гҒЁгҒҢйҮҚиҰҒгҒ§гҒҷгҖӮ

гҒ®жә–еӮҷ гғ© гӮҸ жқҗж–ҷз№Ҡз¶ӯгҒ®ж–№еҗ‘: гҒ•гҒҫгҒ–гҒҫгҒӘж–№еҗ‘гҒ®еүӣжҖ§гҒЁеј·еәҰгӮ’жұәе®ҡгҒ—гҒҫгҒҷгҖӮ

гӮ«гғјгғңгғігғӘгғ

гғҮгӮ№

ign

гҒҠгӮҲгҒійҮ‘еһӢгҒ®жә–еӮҷ

гӮ«гғјгғңгғігғӘгғ гҒ®иЈҪйҖ гҒ«гҒҠгҒ„гҒҰгҖҒиЁӯиЁҲгҒҜжҘөгӮҒгҒҰйҮҚиҰҒгҒӘгӮ№гғҶгғғгғ—гҒ§гҒҷгҖӮз¶ҝеҜҶгҒ«иЁҲз”»гҒ•гӮҢгҒҹиЁӯиЁҲгҒ«гӮҲгӮҠгҖҒе®ҢжҲҗгҒ—гҒҹгғӘгғ гҒҜи»ҪйҮҸгҒ§еүӣжҖ§гҒҢй«ҳгҒҸгҖҒз©әж°—еҠӣеӯҰзҡ„гҒ«гӮӮе„ӘгӮҢгҒҹгӮӮгҒ®гҒ«гҒӘгӮҠгҒҫгҒҷгҖӮ

гғӘгғ гғҮгӮ¶гӮӨгғі

P

еҺҹеүҮ

гӮ«гғјгғңгғігғӘгғ гӮ’дҪңжҲҗгҒҷгӮӢгҒЁгҒҚгҒҜгҖҒж¬ЎгҒ®зӮ№гӮ’иҖғж…®гҒҷгӮӢеҝ…иҰҒгҒҢгҒӮгӮҠгҒҫгҒҷгҖӮ

еҝңеҠӣгҖҒз©әж°—гҒ®жөҒгӮҢгҖҒйҮҚйҮҸй…ҚеҲҶгӮ’гӮ·гғҹгғҘгғ¬гғјгӮ·гғ§гғігҒҷгӮӢгҒҹгӮҒгҒ«гҖҒзІҫеҜҶгҒӘCADгғўгғҮгғ«гҒҢгӮҲгҒҸдҪҝз”ЁгҒ•гӮҢгҒҫгҒҷгҖӮгҒ“гӮҢгҒ«гӮҲгӮҠгҖҒжңҖзөӮзҡ„гҒӘгғӘгғ гҒҢжҖ§иғҪгҒЁе®үе…Ёеҹәжә–гӮ’жәҖгҒҹгҒҷгҒ“гҒЁгҒҢдҝқиЁјгҒ•гӮҢгҒҫгҒҷгҖӮ

еһӢ

жә–еӮҷ

гӮ·гғ§гғі

гғҮгӮ¶гӮӨгғігҒҢе®ҢжҲҗгҒ—гҒҹгӮүгҖҒйҮ‘еһӢгӮ’жә–еӮҷгҒҷгӮӢеҝ…иҰҒгҒҢгҒӮгӮҠгҒҫгҒҷгҖӮ

гӮҜгғӘгғјгғӢгғігӮ°гҒЁз ”зЈЁ - гӮ«гғјгғңгғігғ¬гӮӨгӮўгғғгғ—гҒ®гҒҹгӮҒгҒ®ж»‘гӮүгҒӢгҒӘиЎЁйқўгӮ’зўәдҝқгҒ—гҒҫгҒҷгҖӮ

йӣўеһӢеүӨгҒ®еЎ—еёғ - гғӘгғ гҒҢйҮ‘еһӢгҒ«д»ҳзқҖгҒҷгӮӢгҒ®гӮ’йҳІгҒҺгҒҫгҒҷгҖӮ

жё©еәҰгҒЁең§еҠӣгҒ®ж ЎжӯЈ - жҲҗеҪўдёӯгҒ®дёҖиІ«гҒ—гҒҹзЎ¬еҢ–гҒ«йҮҚиҰҒгҒ§гҒҷгҖӮ

гҒ“гҒ®гӮ№гғҶгғғгғ—гҒ®зҗҶз”ұ

M

гӮўгғғгӮҝгғјгӮә

йҒ©еҲҮгҒӘиЁӯиЁҲгҒЁйҮ‘еһӢжә–еӮҷгҒ«гӮҲгӮҠгҖҒжҲҗеҪўжҷӮгҒ®иӘӨе·®гҒҢдҪҺжёӣгҒ—гҖҒгғӘгғ гҒ®жҖ§иғҪгҒҢеҗ‘дёҠгҒ—гҖҒ競жҠҖгғ©гӮӨгғҖгғјгҒЁгғ¬гӮҜгғӘгӮЁгғјгӮ·гғ§гғі гғ©гӮӨгғҖгғјгҒ®дёЎж–№гҒ®гғӢгғјгӮәгӮ’жәҖгҒҹгҒҷгӮ«гӮ№гӮҝгғ гӮ«гғјгғңгғі гғӯгғјгғү гғӘгғ гҒҢеҸҜиғҪгҒ«гҒӘгӮҠгҒҫгҒҷгҖӮ

гғ¬гӮӨгӮўгғғгғ—гҒЁжҲҗеҪўгғ—гғӯгӮ»гӮ№

гғ¬гӮӨгӮўгғғгғ—гҒЁжҲҗеҪўгҒ®е·ҘзЁӢгҒҜгҖҒеҺҹж–ҷгҒ®гӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгӮ’й«ҳжҖ§иғҪгғӘгғ гҒёгҒЁеӨүиІҢгҒ•гҒӣгӮӢгғ—гғӯгӮ»гӮ№гҒ§гҒҷгҖӮгҒ“гҒ®зҙ°йғЁгҒёгҒ®гҒ“гҒ гӮҸгӮҠгҒҢгҖҒжңҖзөӮиЈҪе“ҒгҒ®еј·еәҰгҖҒеүӣжҖ§гҖҒиҖҗд№…жҖ§гӮ’жұәе®ҡгҒҘгҒ‘гҒҫгҒҷгҖӮ

гӮ«гғјгғңгғігғӘгғ гҒҫ иЈҪйҖ жҘӯ гғ—гғӯгӮ»гӮ№

гғӘгғ д»•дёҠгҒ’гҒЁ

иЎЁйқўеҮҰзҗҶ

гғӘгғ гҒ®ж©ҹжў°еҠ е·ҘеҫҢгҖҒд»•дёҠгҒ’гҒЁиЎЁйқўеҮҰзҗҶгҒ®ж®өйҡҺгҒ§иҖҗд№…жҖ§гҖҒе®үе…ЁжҖ§гҖҒжҖ§иғҪгӮ’зўәдҝқгҒ—гҒҫгҒҷгҖӮ

иЎЁйқў

жә–еӮҷ

й…ҚзөҰ

иЎЁйқўеҮҰзҗҶгҒ§гҒҜгҖҒгғӘгғ гӮ’дёҒеҜ§гҒ«з ”зЈЁгҒ—гҖҒзҙ°гҒӢгҒӘж¬ йҷҘгӮ’гҒҷгҒ№гҒҰеҸ–гӮҠйҷӨгҒҚгҒҫгҒҷгҖӮгғ–гғ¬гғјгӮӯгғҲгғ©гғғгӮҜгҒ«гҒҜзү№гҒ«зҙ°еҝғгҒ®жіЁж„ҸгӮ’жү•гҒ„гҖҒдҝЎй јжҖ§гҒ®й«ҳгҒ„гғ–гғ¬гғјгӮӯжҖ§иғҪгҒЁй•·жңҹзҡ„гҒӘиҖҗж‘©иҖ—жҖ§гӮ’зўәдҝқгҒ—гҒҫгҒҷгҖӮгҒ“гҒ®е·ҘзЁӢгҒ«гӮҲгӮҠгҖҒгғӘгғ гҒҜж§ҳгҖ…гҒӘиө°иЎҢжқЎд»¶дёӢгҒ§гӮӮе®үе®ҡгҒ—гҒҹжҖ§иғҪгӮ’зҷәжҸ®гҒ—гҒҫгҒҷгҖӮ

дҝқиӯ·

гғҸгғҠгӮ°гғһ

гғігӮ°гӮ№

гғӘгғ гҒҜзҙ«еӨ–з·ҡгӮ„еӮ·гҒӢгӮүдҝқиӯ·гҒҷгӮӢгҒҹгӮҒгҒ«гҖҒдҝқиӯ·еұӨгҒ§гӮігғјгғҶгӮЈгғігӮ°гҒ•гӮҢгӮӢгҒ“гҒЁгҒҢгӮҲгҒҸгҒӮгӮҠгҒҫгҒҷгҖӮгҒ“гӮҢгӮүгҒ®гӮігғјгғҶгӮЈгғігӮ°гҒҜгҖҒгғӘгғ гҒ®д»•дёҠгҒ’гӮ’й•·жңҹй–“з¶ӯжҢҒгҒ—гҖҒиҖҗд№…жҖ§гӮ’еҗ‘дёҠгҒ•гҒӣгҒҫгҒҷгҖӮгҒ“гҒ®ж®өйҡҺгҒ§гӮ«гӮ№гӮҝгғ гӮ°гғ©гғ•гӮЈгғғгӮҜгӮ„гғӯгӮҙгӮ’ж–ҪгҒҷгҒ“гҒЁгӮӮеҸҜиғҪгҒ§гҖҒгҒ“гӮҢгҒҜOEMгғ–гғ©гғігғҮгӮЈгғігӮ°гӮ„гғ‘гғјгӮҪгғҠгғ©гӮӨгӮјгғјгӮ·гғ§гғігҒ«гҒҠгҒ„гҒҰзү№гҒ«йҮҚиҰҒгҒ§гҒҷгҖӮ

гҒӘгҒң

гғһгғғгғҲ

гӮҝгғјгӮә

ж©ҹиғҪжҖ§гҒЁиҰӢгҒҹзӣ®гҒ®зҫҺгҒ—гҒ•гӮ’е…јгҒӯеӮҷгҒҲгҒҹгғӯгғјгғүгғҗгӮӨгӮҜз”ЁгӮ«гғјгғңгғігғӘгғ гӮ’иЈҪйҖ гҒҷгӮӢгҒ«гҒҜгҖҒйҒ©еҲҮгҒӘд»•дёҠгҒ’гҒЁиЎЁйқўеҮҰзҗҶгҒҢдёҚеҸҜж¬ гҒ§гҒҷгҖӮдёҒеҜ§гҒ«д»•дёҠгҒ’гӮүгӮҢгҒҹгғӘгғ гҒҜж‘©иҖ—гӮ’и»ҪжёӣгҒ—гҖҒе®үе…ЁжҖ§гӮ’й«ҳгӮҒгҖҒгғӘгғ гҒ®еҜҝе‘ҪгӮ’延гҒ°гҒ—гҖҒгғ©гӮӨгғҖгғјгҒҢжҠ•иіҮгҒ—гҒҹжңҖй«ҳгҒ®гғ‘гғ•гӮ©гғјгғһгғігӮ№гӮ’еҫ—гӮүгӮҢгӮӢгҒ“гҒЁгӮ’дҝқиЁјгҒ—гҒҫгҒҷгҖӮ

е“ҒиіӘз®ЎзҗҶ

1гҒӨгҒ®

nd

гғҶгӮ№гғҲ

е“ҒиіӘз®ЎзҗҶгҒҜгӮ«гғјгғңгғігғӘгғ иЈҪйҖ гҒ«гҒҠгҒ„гҒҰйқһеёёгҒ«йҮҚиҰҒгҒӘгӮ№гғҶгғғгғ—гҒ§гҒҷгҖӮгғ©гӮӨгғҖгғјгҒ®жүӢгҒ«еұҠгҒҸеүҚгҒ«гҖҒгҒҷгҒ№гҒҰгҒ®гғӘгғ гҒҜеҺіж јгҒӘеҹәжә–гӮ’жәҖгҒҹгҒ•гҒӘгҒ‘гӮҢгҒ°гҒӘгӮҠгҒҫгҒӣгӮ“гҖӮ

гғ“гӮёгғҘгӮўгғ«

гӮӨгғігӮ№гғҡгғғгӮҜ

гӮ·гғ§гғі

еҗ„гғӘгғ гҒҜгҒҫгҒҡзӣ®иҰ–жӨңжҹ»гӮ’еҸ—гҒ‘гҖҒиЎЁйқўгҒ®ж¬ йҷҘгҖҒеӮ·гҖҒз©ҚеұӨгҒ®дёҚеқҮдёҖжҖ§гҒҢгҒӘгҒ„гҒӢзўәиӘҚгҒ•гӮҢгҒҫгҒҷгҖӮгҒ“гӮҢгҒ«гӮҲгӮҠгҖҒжңҖй«ҳж°ҙжә–гӮ’жәҖгҒҹгҒ—гҒҹгғӘгғ гҒ гҒ‘гҒҢе·ҘзЁӢгӮ’йҖІгӮҖгҒ“гҒЁгҒҢгҒ§гҒҚгҒҫгҒҷгҖӮ

ж¬Ўе…ғгҒЁ

иҒ–

ж§ӢйҖ зҡ„гҒӘ

гғҶгӮ№гғҲ

гғӘгғ гҒҜжӯЈзўәгҒӘеҜёжі•гҒЁе…¬е·®гӮ’зўәиӘҚгҒҷгӮӢгҒҹгӮҒгҒ«жё¬е®ҡгҒ•гӮҢгҒҫгҒҷгҖӮгҒ•гӮүгҒ«гҖҒиЎқж’ғи©ҰйЁ“гӮ„з–ІеҠҙи©ҰйЁ“гҒӘгҒ©гҒ®ж§ӢйҖ и©ҰйЁ“гӮӮеҸ—гҒ‘гҖҒе®ҹйҡӣгҒ®иө°иЎҢжқЎд»¶дёӢгҒ§гҒ®еүӣжҖ§гҖҒеј·еәҰгҖҒиҖҗд№…жҖ§гӮ’жӨңиЁјгҒ—гҒҫгҒҷгҖӮ

жҝғзё®

е№»жғі

гӮ«гғјгғңгғігғӘгғ гҒ®иЈҪйҖ е·ҘзЁӢгӮ’зҗҶи§ЈгҒҷгӮӢгҒ“гҒЁгҒ§гҖҒй«ҳе“ҒиіӘгғӘгғ гҒ®е„ӘгӮҢгҒҹжҖ§иғҪгҒ®з§ҳиЁЈгӮ’жҳҺзўәгҒ«зҗҶи§ЈгҒҷгӮӢгҒ“гҒЁгҒҢгҒ§гҒҚгҒҫгҒҷгҖӮйҒ©еҲҮгҒӘгӮ«гғјгғңгғігғ•гӮЎгӮӨгғҗгғјгғ—гғӘгғ—гғ¬гӮ°гҒ®йҒёе®ҡгҒӢгӮүгҖҒзІҫеҜҶгҒӘгғ¬гӮӨгӮўгғғгғ—гҖҒжҲҗеҪўгҖҒд»•дёҠгҒ’гҒҫгҒ§гҖҒгҒҷгҒ№гҒҰгҒ®е·ҘзЁӢгҒҢгғӘгғ гҒ®еј·еәҰгҖҒеүӣжҖ§гҖҒиҖҗд№…жҖ§гҒ®еҗ‘дёҠгҒ«иІўзҢ®гҒ—гҒҫгҒҷгҖӮ

жқҗж–ҷгҒ®йҒёжҠһгҖҒиЁӯиЁҲгҖҒе“ҒиіӘз®ЎзҗҶгҒ«жіЁж„ҸгӮ’жү•гҒҶгҒ“гҒЁгҒ§гҖҒгғӯгғјгғүгғҗгӮӨгӮҜгҒ®гӮ«гғјгғңгғігғӘгғ гҒҢдёҖиІ«гҒ—гҒҹгғ‘гғ•гӮ©гғјгғһгғігӮ№гҒЁдҝЎй јжҖ§гӮ’зҷәжҸ®гҒ§гҒҚгӮӢгӮҲгҒҶгҒ«гҒӘгӮҠгҒҫгҒҷгҖӮ

иҮӘи»ўи»ҠгӮ·гғ§гғғгғ—гҖҒгғ–гғ©гғігғүгҖҒгғ©гӮӨгғҖгғјгҒ®гҒ„гҒҡгӮҢгҒ§гҒӮгҒЈгҒҰгӮӮгҖҒгӮ«гғјгғңгғігғӘгғ гҒ®иЈҪйҖ ж–№жі•гӮ’зҹҘгҒЈгҒҰгҒҠгҒҸгҒЁгҖҒжғ…е ұгҒ«еҹәгҒҘгҒ„гҒҹйҒёжҠһгӮ’иЎҢгҒ„гҖҒгғ©гӮӨгғҮгӮЈгғігӮ°дҪ“йЁ“гӮ’зңҹгҒ«еҗ‘дёҠгҒ•гҒӣгӮӢгғӘгғ гӮ’йҒёжҠһгҒҷгӮӢгҒ®гҒ«еҪ№з«ӢгҒЎгҒҫгҒҷгҖӮ

еҪ“зӨҫгҒ®е…ЁиЈҪе“ҒгӮ’гҒ”иҰ§гҒҸгҒ гҒ•гҒ„

гӮ«гғјгғңгғігғӯгғјгғүгғӘгғ

зҶҹз·ҙгҒ—гҒҹиҒ·дәәжҠҖгҒЁй«ҳжҖ§иғҪгҒӘзҙ жқҗгҒ§дҪңгӮүгӮҢгҒҹгӮӘгғ—гӮ·гғ§гғігӮ’иҰӢгҒӨгҒ‘гҒҰгҒҸгҒ гҒ•гҒ„гҖӮ

гӮ«гғҶгӮҙгғӘгғј

ж–°гҒ—гҒ„гғ–гғӯгӮ°

и‘—дҪңжЁ© В© 2026 Top-Fire Carbon Technology Co., Ltd. е…Ёи‘—дҪңжЁ©жүҖжңү. гғ‘гғҜгғјгғҗгӮӨ

IPv6гғҚгғғгғҲгғҜгғјгӮҜгҒҢгӮөгғқгғјгғҲгҒ•гӮҢгҒҰгҒ„гҒҫгҒҷ