自転車ホイールベアリングガイド

自転車のベアリングは一見取るに足らないもののように思えるかもしれませんが、スムーズで効率的な乗り心地を実現するために重要な役割を果たしています。高品質のベアリングは摩擦を軽減し、速度を上げ、さらには自転車のホイールハブの寿命を延ばす効果もあります。自転車の可動部品間の摩擦を軽減することで、ペダリングが楽になり、ステアリングの精度が向上します。

自転車のホイールベアリングとは何ですか?

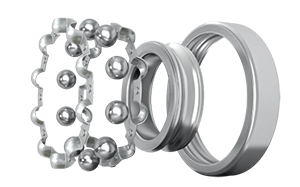

自転車のホイールハブベアリングは、レースウェイ(またはスリーブ)に収められた小さな硬化鋼またはセラミック製のボールで構成された機械部品です。ハブベアリングは、各ホイール(前輪と後輪)のハブ内、通常は車軸とハブシェルの間に配置されています。これらのベアリングは、車軸とハブ間の摩擦を低減し、ホイールが自由かつスムーズに回転できるようにします。

自転車にとってベアリングはなぜそれほど重要なのでしょうか?

1. 滑らかさの向上 :

ベアリングの基本的な機能は、可動部品(ホイールやペダルなど)が軸を中心にスムーズに回転できるようにすることで、摩擦と抵抗を効果的に低減することです。これにより、ペダリングが楽になり、労力が軽減されるだけでなく、ライディングの効率と全体的な体験が大幅に向上します。

2. 車両の寿命を延ばす :

高品質のベアリングは優れた耐摩耗性と耐腐食性を備え、雨、泥、砂といった過酷な環境にも耐え、長期にわたって安定した性能を維持します。一方、低品質のベアリングは損傷を受けやすく、周囲の部品の劣化を早めます。

3. 自転車の安全確保 :

ベアリングの状態は、車両の重要な部品の安定性に直接影響します。深刻な摩耗や故障は、ホイールのふらつき、ハンドルの固着など、様々な問題を引き起こし、操縦性に深刻な影響を与え、安全上のリスクをもたらします。高品質のベアリングを使用することで、故障のリスクを大幅に低減できます。

4. 制御精度の向上 :

ヘッドセットやボトムブラケットなどのコンポーネントに搭載されているベアリングは、ステアリングの感度と車両全体の安定性に重要な役割を果たします。高精度ベアリングは、特にカーブや複雑な地形において、より正確でスムーズなハンドリングを実現します。

自転車のホイールベアリングの種類

セラミック B イヤリング :

セラミックベアリングは、通常、窒化ケイ素などの材料で作られ、転がり抵抗が低く、非常に耐久性が高いことで知られています。スチールベアリングに比べて大幅に軽量で硬度が高いため、最小限の摩擦で回転します。ライダーは、特に高速走行時に、よりスムーズで静かな乗り心地を実感することが多いです。耐腐食性があるため、雨天時や湿度の高い条件でも優れた性能を発揮します。価格は高めですが、特に競技志向のサイクリストにとって、そのパフォーマンス上のメリットは計り知れません。

クロム S ティール B イヤリング :

クロム鋼ベアリングは、最も一般的で手頃な価格の選択肢です。硬化鋼で作られているため、信頼性の高い性能を発揮し、修理や交換も容易です。セラミックベアリングほど滑らかで軽量ではありませんが、適切なメンテナンスを行えば耐久性と信頼性が高く、日常的なライダーや通勤者にとって信頼できる選択肢となります。

ハイブリッド B イヤリング :

ハイブリッドベアリングは、セラミックボールとスチールレースウェイを組み合わせた中間的なベアリングです。この設計は、オールスチールベアリングに比べて摩擦を低減しながら耐久性を維持し、フルセラミックベアリングよりもリーズナブルな価格を実現しています。フルセラミックベアリングにこだわることなく、大幅なパフォーマンス向上を求めるサイクリストにとって、ハイブリッドベアリングはコストパフォーマンスと効率性の絶妙なバランスを実現します。

セラミックベアリングとスチールベアリング – どちらが優れているのでしょうか?

| 特徴 | セラミックベアリング | スチールベアリング |

| 材料 | 窒化ケイ素またはその他の先進セラミック化合物 | クロム鋼または高炭素軸受鋼 |

| 重さ | ライター | 重い |

| 転がり抵抗 | 非常に低く、よりスムーズな転がり | わずかに高いが、それでも効率的 |

| 耐食性 | 優れた性能。湿気や腐食性のある環境に最適。 | 中程度。適切にメンテナンスしないと錆びる可能性がある |

| 耐久性 | 高速、低衝撃条件下でも長持ち | 耐久性が高く、衝撃や荒れた地形にも強い |

| メンテナンス | 正確な設置が必要、設置後のメンテナンスは少ない | メンテナンス、清掃、交換が簡単 |

| 料金 | 高い;プレミアム価格 | 手頃な価格; 予算に優しい |

| 最適なユースケース | ロードレース、トライアスロン、タイムトライアル、パフォーマンス重視のライディング | 通勤、MTB、普段使い、トレーニングライド |

| 初心者向け | 推奨されません。コストが高く、特別な設置が必要です。 | 初心者にとても優しく、シンプルでアクセスしやすい |

| プロモーションの角度 | トップレベルのパフォーマンスと効率を追求するライダーに最適 | 実用的なサイクリングニーズに応える、信頼性が高くメンテナンスの手間が少ない選択肢 |

自転車のベアリングのメンテナンス方法

1. 品質と互換性を重視

ベアリングを購入する前に、優れた耐摩耗性、防水性、防塵性、そして特定の環境(熱、湿度、埃、高負荷など)に耐えられることを確認してください。早期の摩耗や故障を防ぐため、ベアリングのサイズとタイプは自転車の構造に正確に適合している必要があります。

2. 重要な箇所を定期的に点検する

ホイールベアリング、ボトムブラケット、ヘッドチューブヘッドセットなどの高負荷部位は、緩み、異音、抵抗がないか定期的に点検する必要があります。摩耗、固着、その他の問題が見つかった場合は、車両全体の安定性と安全性を損なうのを防ぐため、速やかに交換する必要があります。

3. 科学的な潤滑と保護

非密封ベアリングの場合は、高品質の専用ベアリンググリースを使用し、定期的に給油することをお勧めします。過剰な給油は抵抗を増加させ、潤滑不足はベアリングを損傷する可能性があります。そのため、メンテナンス間隔は、走行頻度や環境(湿度や埃など)に応じて柔軟に調整する必要があります。

自転車のホイールベアリングを交換する必要がある兆候

ハブの遊び: ホイールを握って振ったときに左右に動いたりぐらついたりを感じる場合は、ベアリングまたはその調整が損なわれていることを意味します。

回転が荒い:ホイールを手で回すと、滑らかに静かに回転するはずです。擦れるような音、ざらつき、抵抗感がある場合は、ベアリングが摩耗している可能性があります。

きしみ音や異常な音: 走行中にきしみ音、カチカチ音、きしみ音が聞こえる場合は、ベアリングの損傷または汚染を示している可能性があります。

自宅でベアリングの状態をテストする方法

ホイールを回す:自転車を持ち上げて、ホイールが自由に回転するようにします。ガタガタ感や異音がないか注意深く耳を澄ませ、回転がスムーズかどうかを確認します。

よくある質問

自転車のホイールベアリングはどのくらいの頻度で交換する必要がありますか?

通常、ベアリングの寿命は走行条件やメンテナンスによって異なりますが、3,000マイルから10,000マイルです。ガタツキ、ガタ、異音に気付いたら、交換時期です。

いつでもセラミックベアリングにアップグレードできますか?

はい、可能です。ただし、ハブの互換性と取り付け精度をご確認ください。セラミックベアリングは摩擦が少ないですが、価格が高くなります。

ホイールベアリングは自転車の速度に影響しますか?

もちろんです!高品質でメンテナンスの行き届いたベアリングは摩擦を減らし、転がり効率を向上させるので、少ない労力でより速く走ることができます。